型號: specialty_chemistry

Environmental Protection, Waste Reduction and Reuse

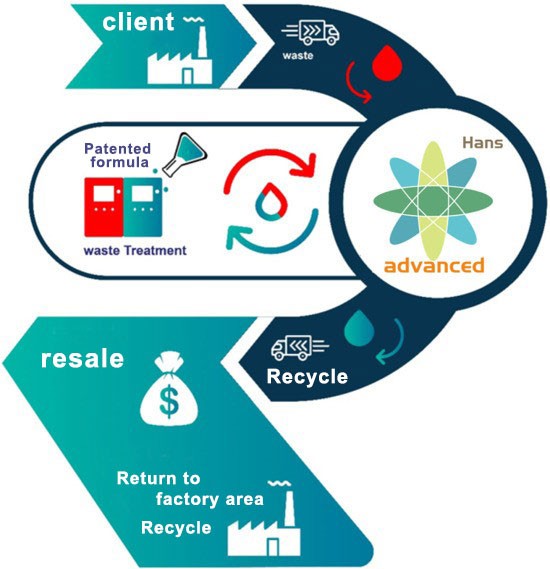

Hanstech Semiconductor Waste Treatment Company - Semiconductor Waste Recycling and Reuse

Nowadays, semiconductor waste treatment is an important issue, how to convert the waste liquid into recycling and reuse, is gradually being emphasized by the semiconductor industry. Hanstech, as a semiconductor waste treatment company, owns special semiconductor waste recycling patented formulas, specializing in the treatment of semiconductor process liquid waste. Through these patented semiconductor process waste recycling formulas, carbon dioxide produced by traditional waste treatment methods is reduced, so that we can effectively resource waste, thus achieve a circular economy and enhance corporate value.

Semiconductor waste liquid recycling and reuse solutions

How to completely remove hydrogen peroxide without damaging the solvent base?

Highly safe method

Non-destructive reaction

Low environmental contamination

Recyclable

Differences from Conventional Technology

| Conventional Technology | Solution | |

|---|---|---|

| Treatment | Incineration | Biological treatment |

| Risks of treatment | Explosion due to instantaneous decomposition of hydrogen peroxide | Temperature reaction |

| Treatment time | short | 3Hr/batch |

| Wastewater Discharge Volume | 800kg/Ton | 650kg/Ton |

| Fixed pollution sources | Air emissions Large amount of CO2emissions | release O2 |

| Resource activation and reuse | None | Industrial grade products/electronic grade (re-purification) |

| Technical Characteristics | None | Safe and non-destructive |

Patented Technology

Hanstech has been actively researching and developing a patented semiconductor waste treatment formula that removes hydrogen peroxide from acidic and alkaline waste solvents generated in the semiconductor process, significantly reducing the risk of gas explosions in the subsequent purification process. In addition to the development of the patented formula, Hanstech has also obtained the qualification as a recycling organization (control number) from the Environmental Protection Agency. Hanstech has begun the collection and transportation service to help semiconductor manufacturers achieve the goal of waste reduction/carbon reduction through the patented formula for semiconductor waste treatment.

Applications

Hanstech's products of patented waste liquid recycling formula can be used not only in the semiconductor production, but also in the petrochemical industry (purification of aromatic hydrocarbons/purification of acid gases), the printing ink industry (to increase ink storage stability/prevent nozzle clogging), the dyeing and finishing industry (dyestuff decomposition enhancers/improvement of the characteristics of synthetic fibers), and the electronics industry (to improve the efficiency of lithium-ion batteries/semi-conductor cleaning process), etc. We also provide product application and supporting programs for various industries. Hanstech Advanced Materials is committed to creating environmentally friendly semiconductor waste treatment products with professional technology and services. We hope to provide innovative material solutions and integrated services to help our customers improve their competitive advantages by streamlining costs and increasing efficiency.

Petrochemical industry

Aromatic hydrocarbon purification of acid gas

Printing and ink industry

Increase ink storage stability to prevent nozzle clogging

Dyeing and finishing textile industry

Dye Disintegration Enhancer Improves Synthetic Fiber Properties

Electronics industry

Improving the efficiency of lithium battery and Semiconductor cleaning in production