ESG and net-zero develop new situation, TRUSVAL showcases green process solutions at SEMICON

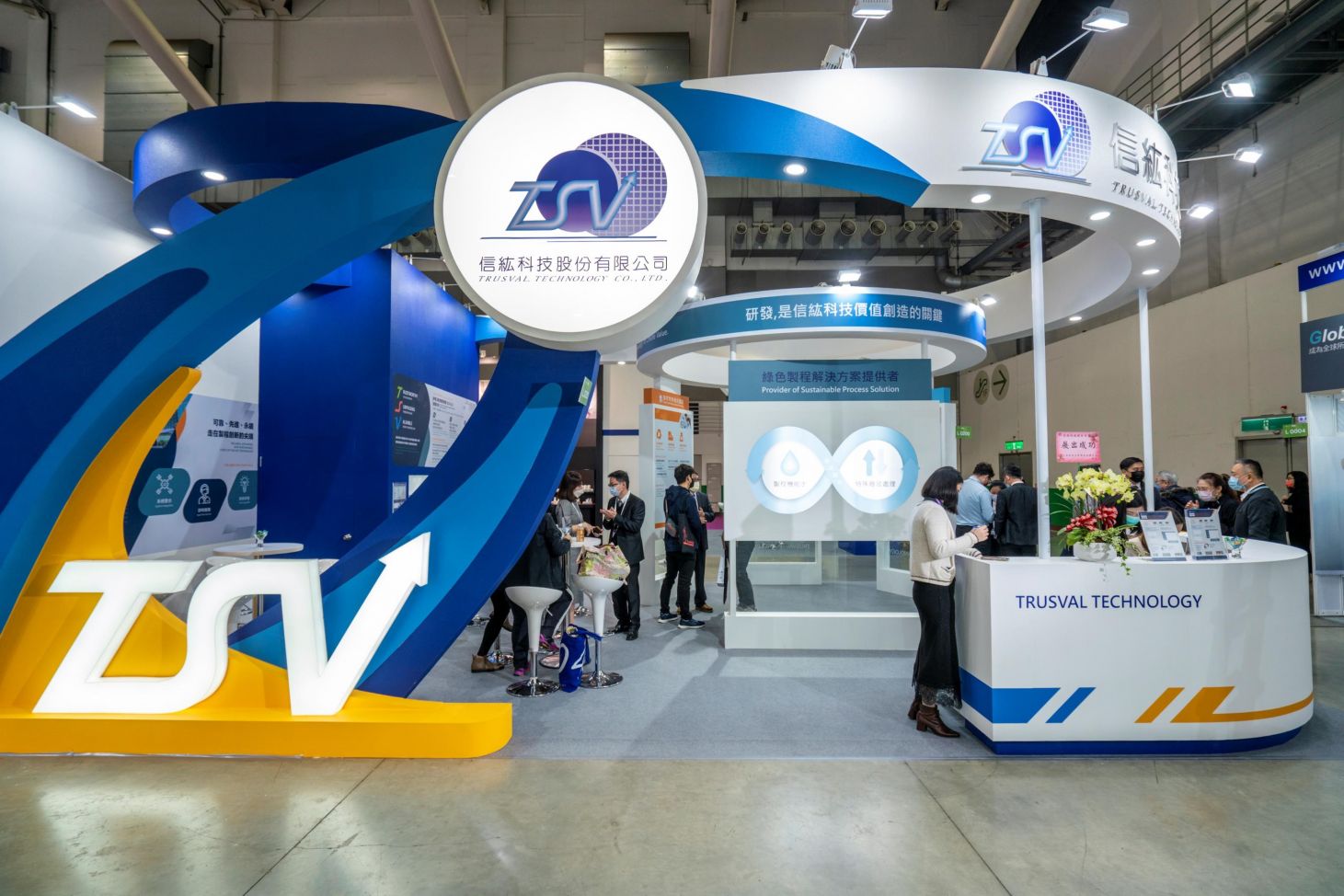

ESG and sustainable development have become the key competitiveness for the resilience of Taiwan's semiconductor industry chain in the next decade. Major international semiconductor wafer manufacturers have successively invested capital expenditures in green manufacturing to move towards the mid- to long-term goal of net zero. TRUSVAL Technology Co., Ltd. (hereinafter referred to as "TRUSVAL" or "the Company", stock code: 6667) has been developing semiconductor green process solutions for nearly 10 years. This time, it has been invited to participate in the annual International Semiconductor Exhibition (2021) for the sixth time. SEMICON Taiwan) will be held for three days starting from December 28 (Tuesday) on the 4th floor of Hall 1 of Taipei Nangang Exhibition Center (booth number L0200). With the brand image of the company's concept "Infinity Symbol ∞", green process solutions will be showcased. The research and development strength of the company demonstrates the company's complete professional technology in the three major fields of "system integration", "process functional water" and "process special waste liquid", as well as real-time flexible services, long-term joint development of solutions with customers, etc., reliable, advanced and Sustainable competitiveness highlights that TRUSVAL is at the forefront of process innovation and helps customers achieve green manufacturing and move towards the goals of net-zero and ESG sustainable development.

TRUSVAL is committed to becoming a complete high-tech industrial process system integrator. This time, the company's concept of "infinity symbol ∞" is still used as the main axis in the booth design, showing the high competitiveness of "Trustworthy, Surpassing, Valuable" R&D and service values, and It invests about 3% of its revenue in research and development expenses every year to continue to develop core technologies. In addition to improving green process solutions, including factory chemical supply/recycling systems, process functional water and other related equipment upgrades and service quality, this year it also demonstrated the company's new The research and development results "Electrostatic Dissipative Diamond-Like Carbon (ESD-DLC) Film Coating Technology" and the agency's "ultra-trace substance detection, surface defect detection solution"equipment were announced at"TechXPOT Innovation Technology" at 3:00 pm on December 28 In the meeting, regarding the topic of "high-tech factory facilities", TRUSVAL shared its latest professional technology on "the best new solution for high-temperature electrostatic protection: electrostatic dissipative diamond-like carbon coating (ESD-DLC)". TRUSVAL also Through the high visibility and professional gathering of the exhibition, we can strive for more new customers and new order cooperation opportunities, and create long-term and stable operational growth momentum for the company.

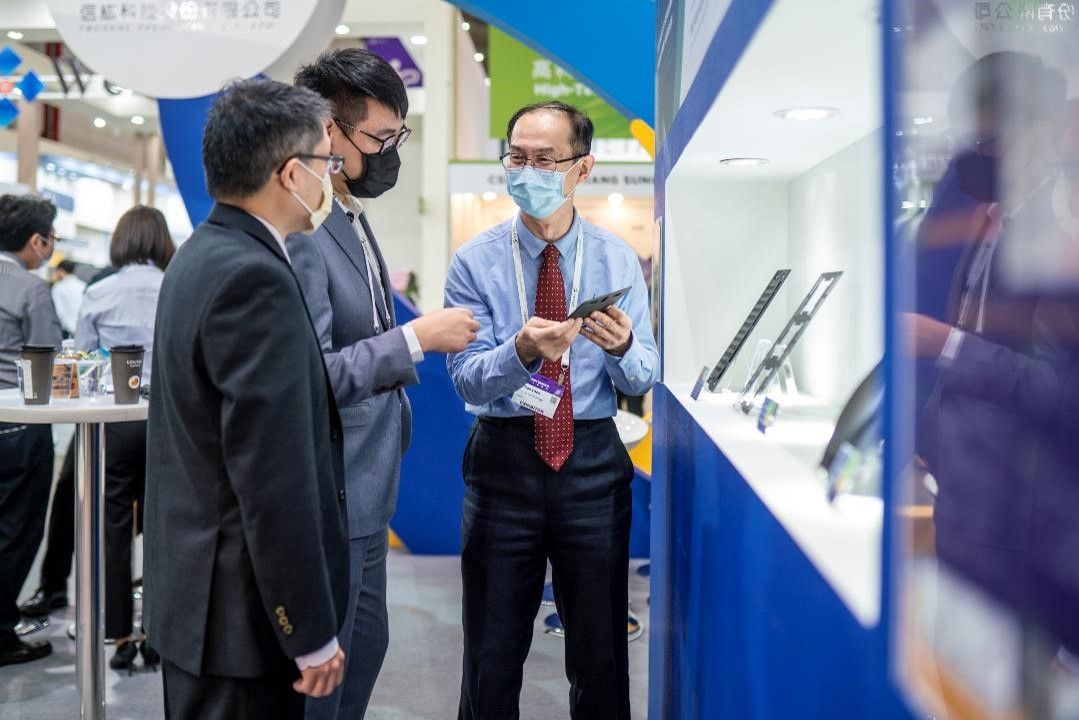

TRUSVAL and ITRI jointly developed the latest ESD-DLC technology. Its multi-layer structure design, amorphous structure and excellent wear resistance, coupled with the use of an improved magnetic filter arc ion system and high chemical stability, achieve excellent resistance. As a result of static electricity and good acid and alkali resistance, advanced surface modification technology has been successfully used on advanced semiconductor packaging and testing carrier boards and carrier disks, which can extend the service life of packaging and testing carrier boards by at least 3 times, replacing the old ones that are not resistant to alkali cleaning. The hard-anodized treatment method creates electrostatic protection holes due to peeling of the film due to collision or other cleaning factors, bringing new breakthroughs in Taiwan's advanced packaging process. TRUSVAL has gradually built up the production capacity of ESD-DLC coating technology and gradually introduced production and proofing. It is expected to start small quantities of production next year (2022). It is currently the only company in the industry that can achieve stable mass production. At this stage, customers are mainly advanced semiconductors. Focusing on the packaging and testing precision processing industry, we also work closely with customers to develop different types of applications and continue to prototype. We hope that the benefits will gradually unfold and add growth momentum to the company's future operations.

Furthermore, judging from the fact that TRUSVAL’s overall revenue in the first November of this year hit a record high for the same period in history, with an annual growth rate of 34%, the existing high-tech industrial process factory supply system integration and dismantling machine service engineering business are in good shape. In addition to performance growth, the revenue proportion of green process solutions has increased from 5.56% in 2018 to 13% in the first three quarters of 2021. Among them, "process functional water" has followed the trend of international semiconductors towards advanced processes and green processes. On the one hand, it uses gas-liquid phase mixing technology to combine carbon dioxide and water "soda machine", and continues to contact and verify customers with mature processes. On the other hand, from the third quarter of this year, the application scope of alkaline functional water equipment has expanded from semiconductor advanced processes The customer's front-end yellow light post-process cleaning has been expanded to related cleaning in the back-end packaging process. In the future, as semiconductor customers develop towards advanced process technology and environmental protection and energy saving, there will also be a steady demand for TRUSVAL's "process functional water", contributing The company's good operating performance.

According to the year-end overall OEM semiconductor equipment forecast report released by SEMI (International Semiconductor Industry Association) at the annual SEMICON Japan, the total sales of semiconductor manufacturing equipment by global equipment manufacturers (OEMs) in 2021 will hit US$103 billion. A new record, an annual increase of 45%, and will reach a new high of US$114 billion in 2022. It can be seen that the growth of global semiconductor equipment market demand continues to strengthen. Looking at regional differences, Taiwan's equipment expenditure is expected to grow in 2022 and 2023. Taking back the top spot in 2018 will help TRUSVAL expand its business. Looking forward to future operations, TRUSVAL is highly confident in its operational growth. Judging from the current order visibility of TRUSVAL's orders on hand, which has been extended to 2022, it not only benefits from the construction and capacity expansion of new factories such as Zhuke Wafer Factory and Nanke Advanced Process Factory, but also contributes to the overall implementation. With the construction project progressing as expected, the company's operating performance will maintain good momentum. Next year, it will continue to expand its market share among advanced customers, expand its customer base through service diversification, and strive to move towards a high-tech industrial process system integrator.

from:https://www.trusval.com.tw/big5/news_page_66_1